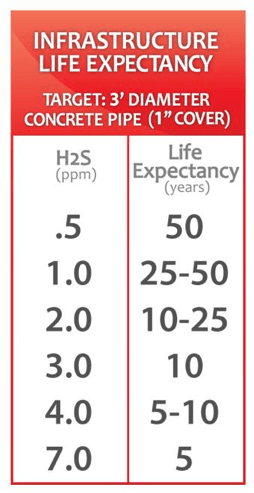

Treatment of sulfide within collection systems is a difficult challenge. The organisms responsible for the production of sulfide are ubiquitous. They will grow within a collection system at any point where oxygen is limiting. Anaerobic or anoxic zones within a collection system create the perfect environment for the production of sulfide. Sulfide producing organisms harvest all oxygen molecules from oxygen rich sulfur compounds (e.g. sulfate, sulfite) commonly available within the wastewater for use in their metabolic processes. The resulting sulfide production causes significant odor issues and tremendous damage to infrastructure primarily from corrosion. Corrosion occurs as sulfide is converted to sulfuric acid by another class of organisms that use sulfide as an energy source.

Nitrate-based chemistry, as a basis of H2S control, can be very expensive, particularly in those situations where sulfide has already formed within the wastewater prior to nitrate addition. Under these circumstances, significant quantities of nitrate are necessary to induce organisms to consume sulfide. Nitrate seems better suited for sulfide control as a deterrent to formation, not for sulfide control after it has already formed. Studies conducted using nitrate in those situations where sulfide was a pre-existing condition prior to the addition of nitrate indicate that costly amounts of the chemical are necessary to control sulfide.

Source’s patent-pending ETX Process was developed to cost-effectively destroy sulfide that is present at the delivery point while also providing treatment for long retention times within force mains and gravity sewer systems. The method also acts to kill those organisms responsible for sulfide production as a third benefit.

The ETX Process occurs when Source’s ETX catalyst, a complex organic compound, is combined with selected oxidizing agents, i.e. H2O2, in solution. This attacks the H2S problem in a two-fold manner. First, any H2S already present will be oxidized within minutes. Secondly, hours later when the oxidation is completed, formation of new H2S is prevented for up to 60 hours!

Control of sulfides within variable length and multiple line collection systems can be complex as no two systems are identical. For this reason, Source can provide ETX Process blends that are specific to the customer’s needs. This allows for the most efficient and cost-effective treatment for long detention times on the market today.

With proper set-up, the ETX Process line of products will solve sulfide control issues effectively and economically. This is truly a break-through technology that can provide the control for sulfide that has been sorely needed within wastewater treatment.